Morpack (Flexible Packaging Division)

Morpack is Bagco's flexible packaging division that designs, manufactures, and supplies a range of laminated and flexible packaging solutions for fast-moving consumer goods and industrial customers.

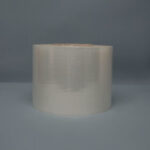

Morpack specializes in flexible packaging solutions, a modern form of packaging that is light-weight, versatile, and designed to extend shelf-life and enhanced product presentation. Morpack combines modern file extrusion and lamination technologies with in-house printing and converting (zipper, spout, gusseting, resealable closures) to deliver high performance, sachets, and roll stock tailored to brand, product and supply-chain needs.

Key Strength

End-to-end flexible packaging capability

From film extrusion to printing, lamination, conversion, and finishing

Advanced lamination and printing capabilities

Custom roll films tailored to different product categories

Strong barrier properties safeguarding against moisture, oxygen, aroma and light to protect product integrity

High-definition graphics to support brand visibility

Compliance with food-grade safety standards for packaging consumables

Applications & Use-Case Scenarios

Snack & Confectionaries (PrintRoll + Barrier Shield)

Use: Printed rollstock for bag-in-box or farm-fill-seal snack packs; barrier laminate preserves crispness and flavours.

Benefit: Attractive printed packaging + extended shelf life and higher re-orders.

Powdered Drinks & Milk Powder (BarrierShield + SealPlus)

Use: High-barrier roll films for sachets and multi-serve pouches produces by converters.

Benefit: Moisture and oxygen control reduced caking and extends shelf life.

Detergent Refils (Morpack Lite + SealPlus)

Use: Lightweight films optimized for powdered/liquid refills on automated lines.

Benefit: Lower transport/ logistic cost and reduced plastic use.

Spice and Seasoning Packs (BarrierShield & Clearview)

Use: Partial clear window with barrier laminate for visual inspection while protecting aroma.

Benefit: Consumer trust for product visibility + aroma protection.

Multipacks & Shrink Bundles (ShrinkWrap)

Use: Overwrap films for bundling retail packs

Benefits: Secure multipacks for transit and retail display

Morpack

(Flexible Packaging Division)

Morpack specializes in flexible packaging solutions, a modern form of packaging that is lightweight, versatile, and designed to extend shelf life and enhance product presentation.

Morpack combines modern film extrusion and lamination technologies with in-house printing and converting (zipper, spout, gusseting, reusable closures) to deliver high-performance, satchets, and roll stock tailored to brand, product, and supply-chain needs.

Morpack Products

The Morpack (flexible packaging division) product names and descriptions (typical roll film products) includes:

- Barrier Shield: Multi-layer laminates engineered to control moisture, oxygen, aroma and light ingress. Ideal for spices, powdered milks, and aroma-sensitive products.

- Heat sealable film structure

- The flagship cement bag in Nigeria, built for maximum strength and reliability in the building materials sector.

- Features: Heavy-duty weave, UV resistance, moisture barrier, high load capacity.

- Transparent & Window Films: Clear/transparent laminates and window-compatible structures that shows the product inside while ensuring necessary barrier properties.

- Films for multipack shrink-wrapping and overwrapping applications

Ordering & Technical Notes

Here’s a breakdown of what buyers need to provide for Morpack to supply accurate rollstock.

- Artworks: Vector-based artwork, dielines for label layout, bleed + safe zones (see earlier explanation).

- Required roll width & core size: Width in mm and core inner diameter

- Film structure request: Specify barrier/heat-seal needs or allow Morpack to recommend.

- Printing specs: Number of colours, full print vs spot print, Pantone/CMYK references.

- Machine compatibility: FFS machine type and speed; sealing jaw type and temperature range.

- MOQ & run length: Minimum order quantities vary by structure and print; typical MOQs set per product.

- Lead times: Depending on artwork approval, tooling and run size, prototype/sample lead times shorter; full production lead times longer.

See More Packaging Solutions Below

Bagco PP Woven Bags

At Bagco Packaging Solutions Limited, our Polypropylene (PP) woven bags division represents the company’s heritage and leadership in industrial and commercial packaging.